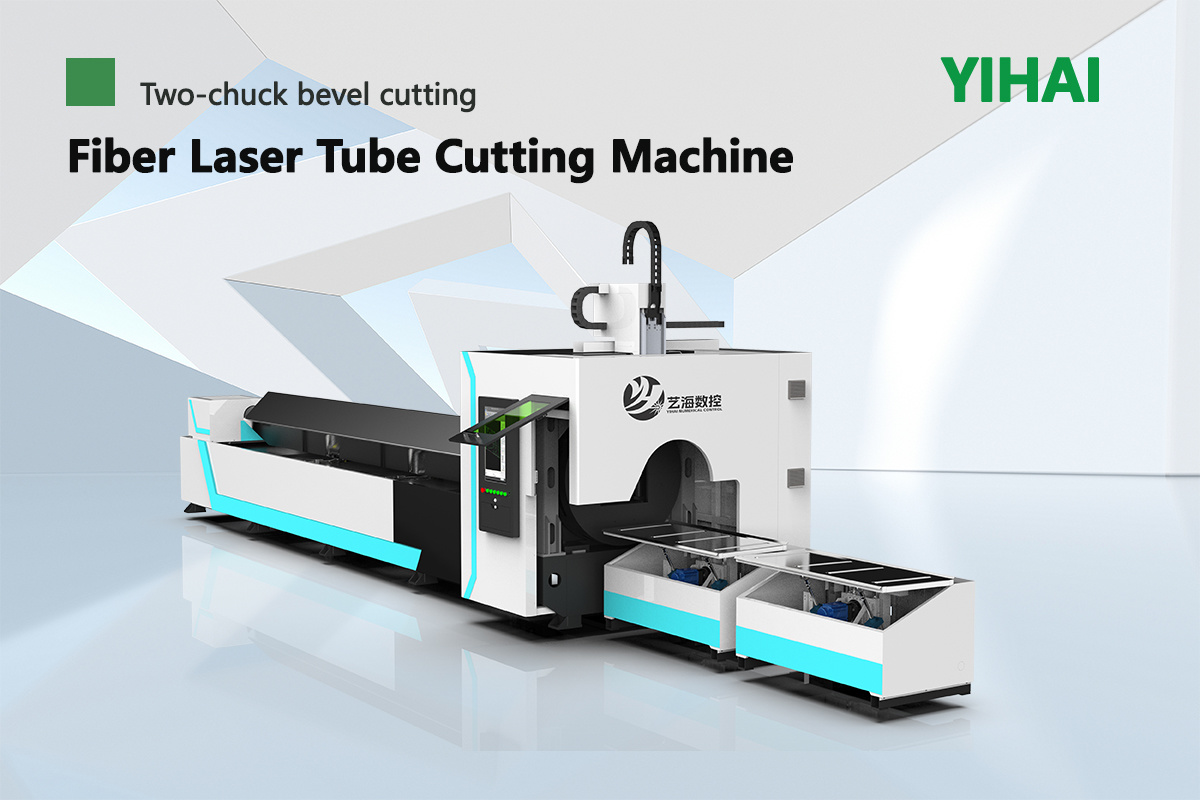

460 Bevel Fiber Laser Tube Cutting Machine

这里是标题一h1占位文字

Classification :

Product Description

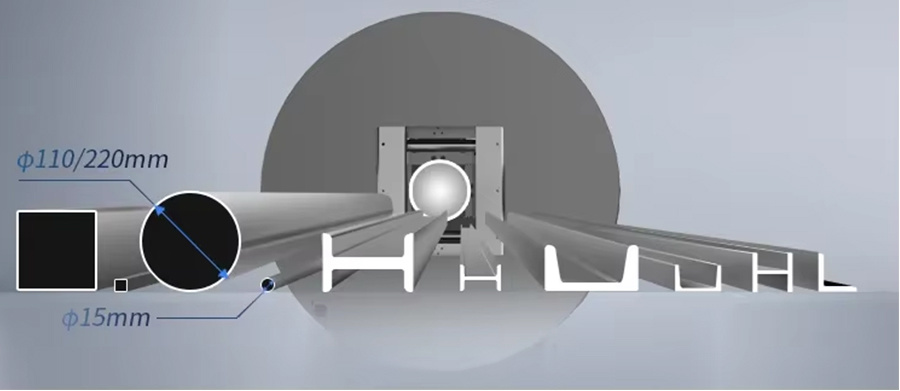

2024 New Design 3kw 6kw Metal Laser Cutting Machine for Pipe Cut Fiber Laser Tube Cutting Machines Cypcut System

Product Specifications

| No | item | Data |

|---|---|---|

| 1 | Name | Pipe Laser Cutting Machine |

| 2 | Laser Power | 1000W 2000W 3000W 6000W |

| 3 | Laser source | Reci/ MAX/ Raycus |

| 4 | Laser head | Raytools |

| 5 | Control system | WEIHONG |

| 6 | Water chiller | S&A |

| 7 | Driver system | YASKAWA |

| 8 | Guiderail brand | HIWIN |

| 9 | Working voltage | 220V |

| 10 | Certification | CE |

| 11 | Cutting thickness | 0-16mm |

Product configuration

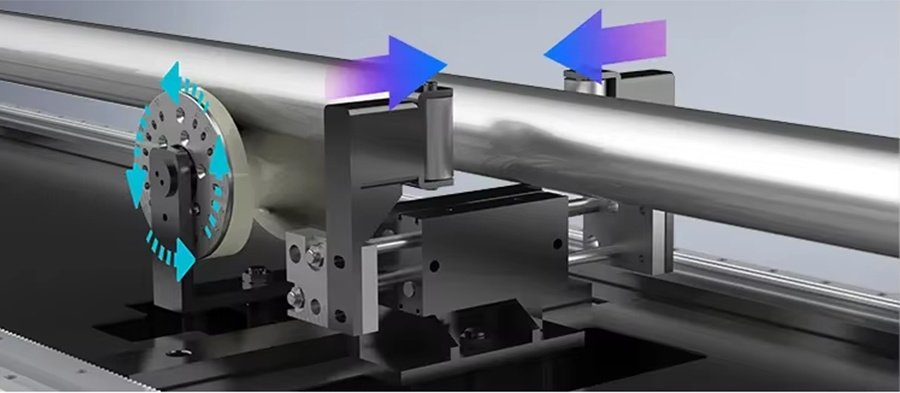

1.stabilization

A stable support that prevents shaking can prevent large deflection of the pipe and improve the cutting accuracy.

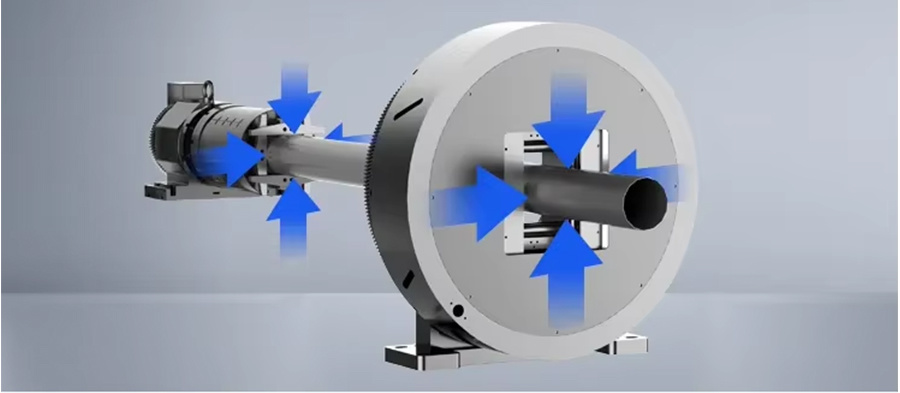

2.Two chucks with easy loading

Front and rear double pneumatic chuck, self-centering throughout the stroke, high positioning accuracy, one-key clamping, adjustable clamping force, stable and efficient.

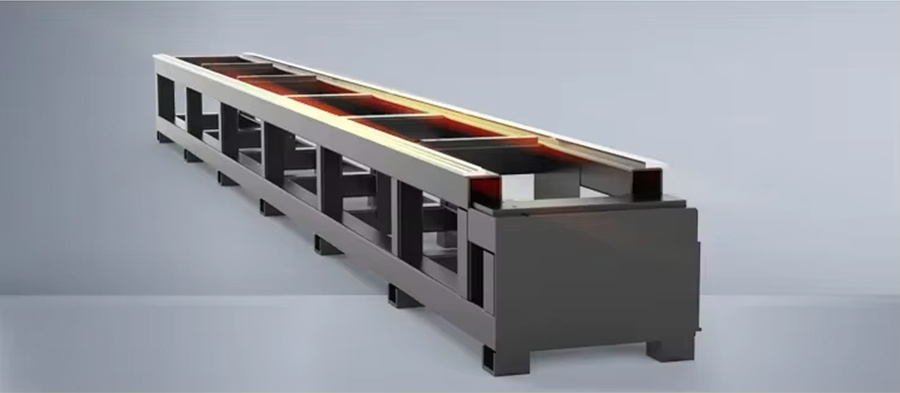

3.Robust frame

The structure of the bed is optimized and upgraded. After high-temperature annealing, vibration aging and other precision processing, the welding and process stresses are effectively eliminated, which ensures the accuracy and reliability of the bed.

Product display

Application Areas

Why Choose Us

Jinan Yihai Laser Technology Co., Ltd.

is a privately-owned enterprise specializing in the production and processing of CNC equipment, CNC cutting machines, plasma cutting machines,laser cutting machines, stone carving machines, advertising carving machines, woodworking carving machines, and other products. The company is headquartered globally, and the Yihai CNC Equipment Manufacturing Factory in Licheng District, Jinan has a complete and scientific quality management system. The integrity, strength, and product quality of Jinan Yihai CNC Equipment Manufacturing Co., Ltd. have been recognized by the industry. Welcome friends from all walks of life to visit, guide, and negotiate business with Jinan Yihai CNC Equipment Manufacturing Co., Ltd.

● Online service:

We have big online video data that including machine running test, installing, debugging, maintain,trouble removing,etc. Most of issue you considerate, you will find the solution in the data. Surely,we can face time by whatsapp, skype, wechat to make guide, training. I will 7*24 hours online. You can call me at anytime if you are urgent

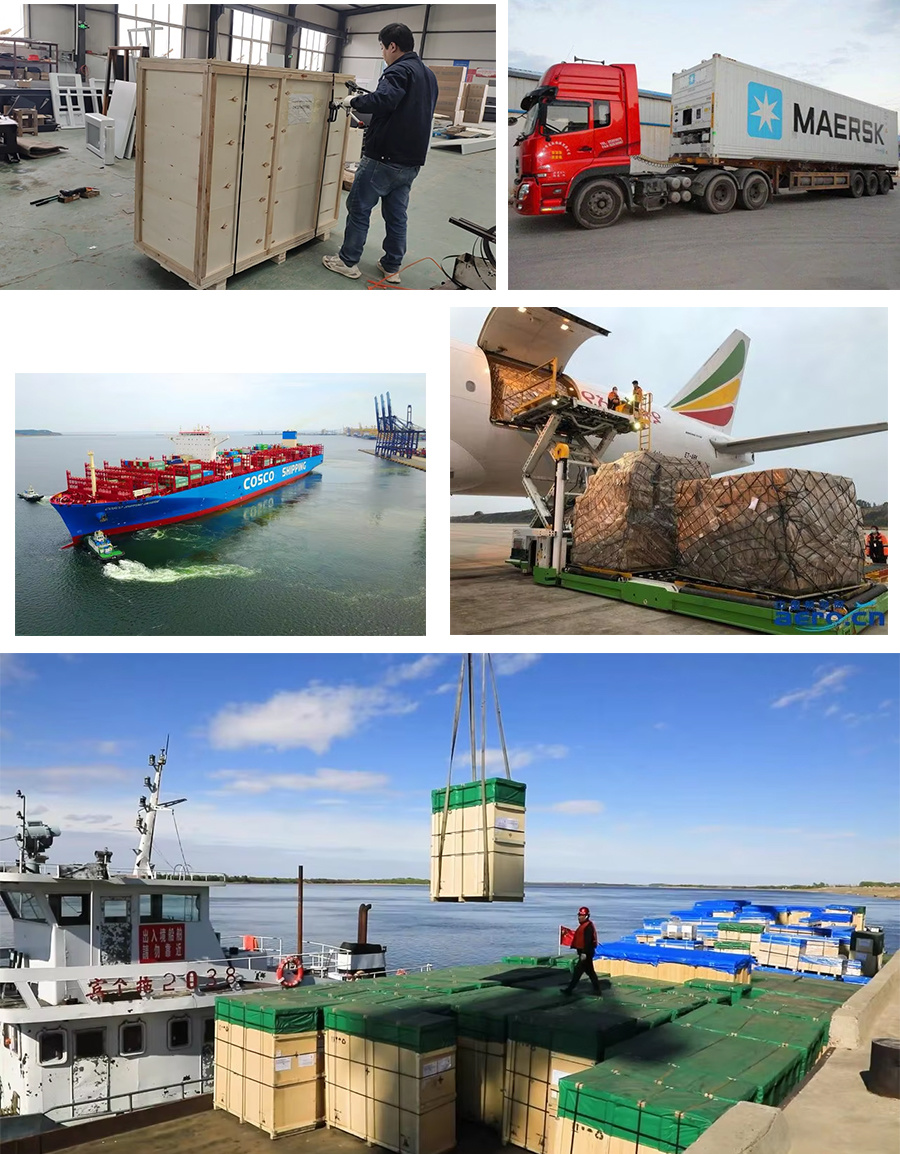

Packing & Delivery

Package

1) Whole film packaging machine.

2) Anti-collision package edge.

3) Fumigation-free plywood wooden box with an iron-binding belt.

4) According to the customer's requirements for loading the whole container or LCL at Qingdao Port.

Delivery Terms

1) The machine will be produced after received your deposit, its need about 15-20 working days to produce the machine after get your deposit.

2) After the machine is ready, we will test it very carefully, and ensure everything is OK.

3) Then we will show you the machine photos and the testing video.

4) After you agree, please finish the balance payment.

5) Finally, all things are tested well, then we arrange the delivery.

The laser steel cutting machine is a cutting-edge piece of equipment that has brought revolutionary changes to the metalworking field.

This machine operates with remarkable precision, using a powerful laser beam to accurately cut through steel. It can handle various thicknesses of steel, from thin sheets to thick slabs, with ease. The laser's high energy and focus ensure clean and smooth cuts, minimizing the need for post-processing.

The laser steel cutting machine offers several outstanding features. Firstly, its cutting speed is incredibly fast, significantly improving production efficiency. It can complete complex cutting patterns in a short time, meeting the demands of high-volume manufacturing. Secondly, the machine provides excellent dimensional accuracy, allowing for the creation of precisely shaped components. This is crucial in industries where tight tolerances are required.

Moreover, the laser cutting process is highly automated. Operators can input the design specifications into the machine's control system, and it will execute the cutting operation precisely as programmed. This reduces the reliance on manual labor and minimizes the risk of errors.

The machine also offers flexibility in terms of the types of cuts it can make. It can perform straight cuts, curved cuts, and even intricate designs with ease. Additionally, some advanced models may have features such as automatic material feeding and unloading, further enhancing the workflow.

In addition to its cutting capabilities, the laser steel cutting machine is known for its reliability and durability. High-quality components and a robust construction ensure long-term stable operation, minimizing downtime and maintenance costs.

The applications of the laser steel cutting machine are extensive. It is widely used in the automotive industry for manufacturing car parts, in the aerospace sector for crafting aircraft components, and in the construction industry for fabricating metal structures. It is also essential in the production of various industrial machinery and consumer goods.

In summary, the laser steel cutting machine is a state-of-the-art technology that combines precision, speed, flexibility, and reliability. It has become an indispensable tool in modern metalworking, enabling manufacturers to produce high-quality steel products with efficiency and accuracy. Whether for large-scale industrial operations or smaller workshops, this machine is transforming the way steel is cut and fabricated.

FAQ

Q: What about the leadtime?

Q: Do you have after sales support?

Q: How about warranty?

Q: Do you have CE document and other documents for customs clearance?

460 Bevel Fiber Laser Tube Cutting Machine

GET A FREE QUOTE