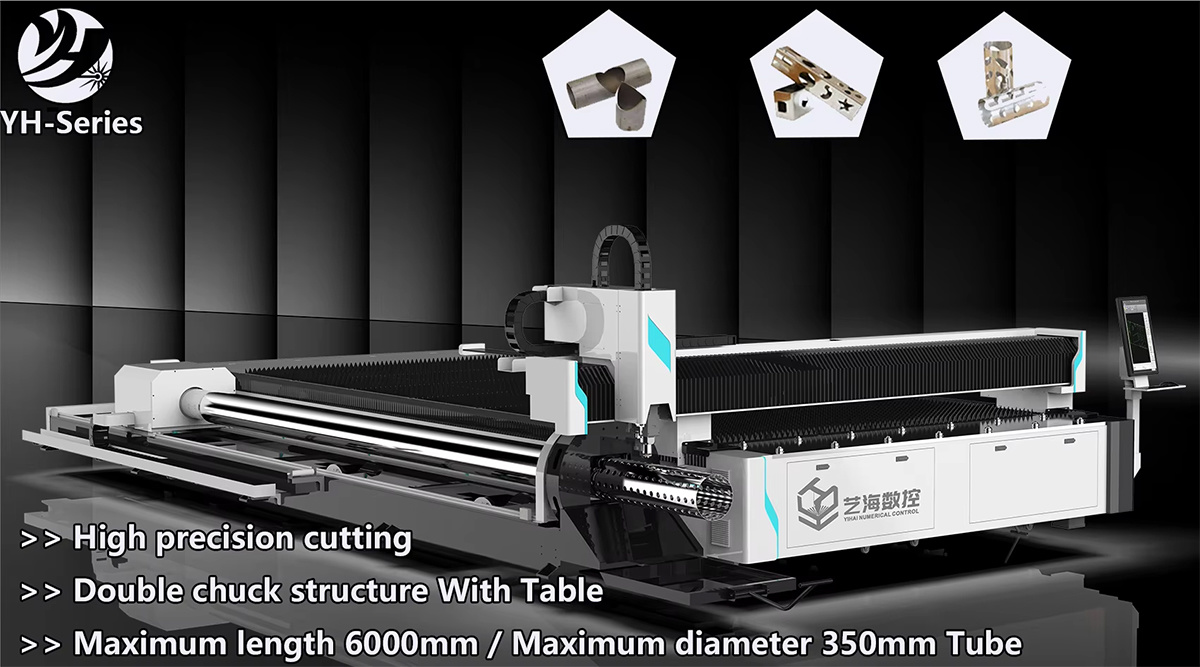

Sheet And Tube Fiber Laser Cutting Machines

这里是标题一h1占位文字

Classification :

Product Description

Product Specifications

| No | item | Data |

|---|---|---|

| 1 | Laser Power | 1-30KW |

| 2 | Movement Speed | 200m/min |

| 3 | Positional Accuracy | ±0.02mm |

| 4 | repeated positioning accuracy | 0.02mm |

| 5 | Effective cutting diameer of round tube | Ф20-Ф650 |

| 6 | Efective cutting diameter of square pipe | □20-□254 |

| 7 | Cut lengt | |

| 8 | accelerated speed | 0.8G/1.0G/1.5G/2.0G |

| 9 | Gross weight | 3000kg |

| 10 | Machine warranty | 2 years |

Product Configuration

|

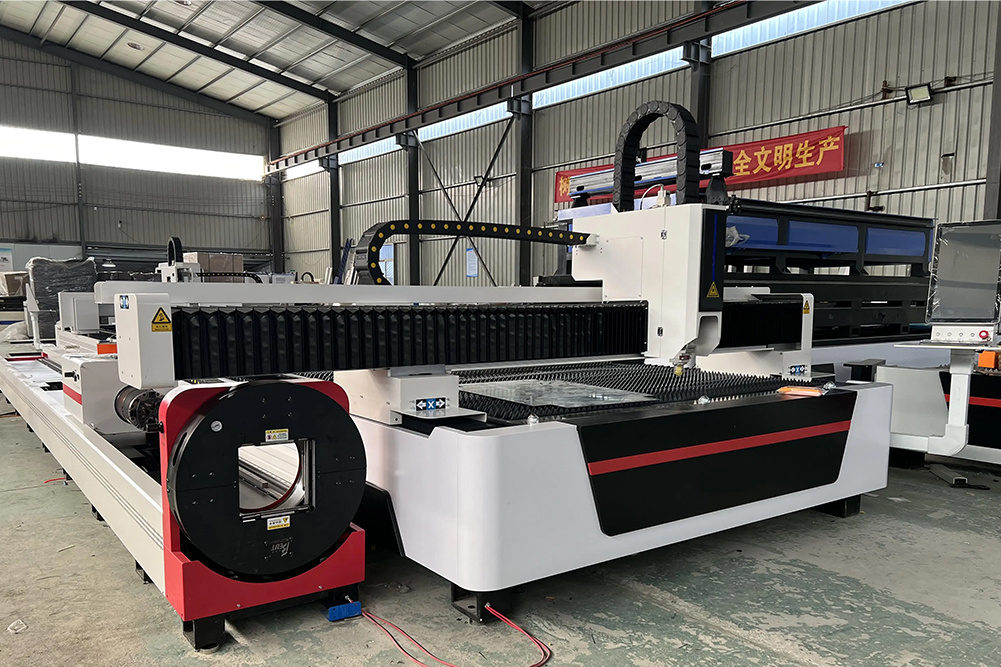

Heavy duty frame High-strength alloy steel welded bed, which is tensile-resistant, non-deformable, and rock-solid, effectively reducing the impact of thermal deformation and thermal stress on the machine tool, ensuring that the machine tool operates at high speed without shaking and maintains high precision for a long time. |

|

Laser source Reci/Raycus/MAX/IPG, multiple choice Different brands, different laser power are available. The higher power, the thicker cutting thickness.Supply laser power from1kw to 12kw, and more higher 15kw, 20kw,30kw |

|

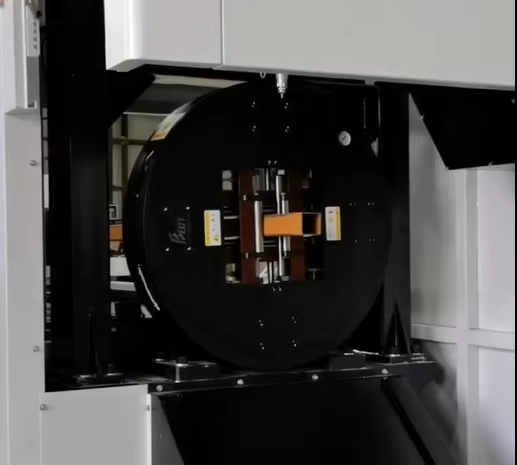

Pneumatic chuck The pneumatic chuck adopts a cylinder structure inside, which can effectively control the pressure of the chuck, thus accurately clamping the workpiece and ensuring machining accuracy. Easy to operate: The pneumatic chuck is controlled by an air source, which is easy to operate and can achieve automatic clamping and loosening, improving work efficiency. |

|

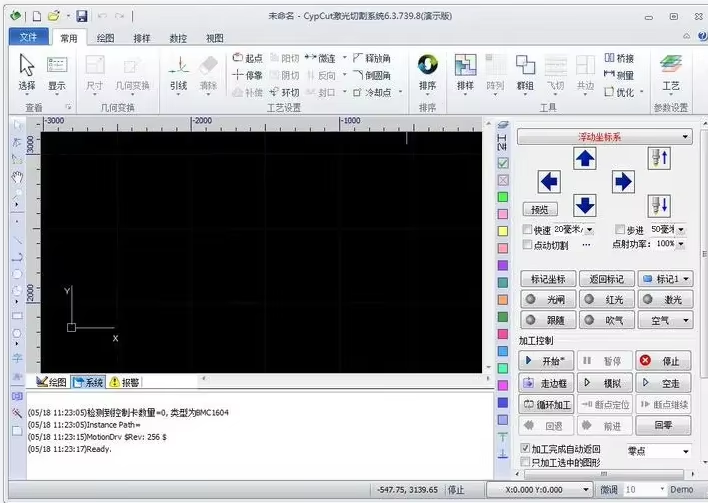

Intelligent Control System CypCut plane cutting software is a set of an software specially developed for the deep customization of the laser cutting industry,easy to use, rich in functions, suitable for various processing occasions. Edge finding aid Dual-drive deviation self-correcting two-stage capacitive edge seeking |

|

High quality guide rail Taiwan HIWIN guide rails and racks are used to ensure the accuracy and stability of machine operation. |

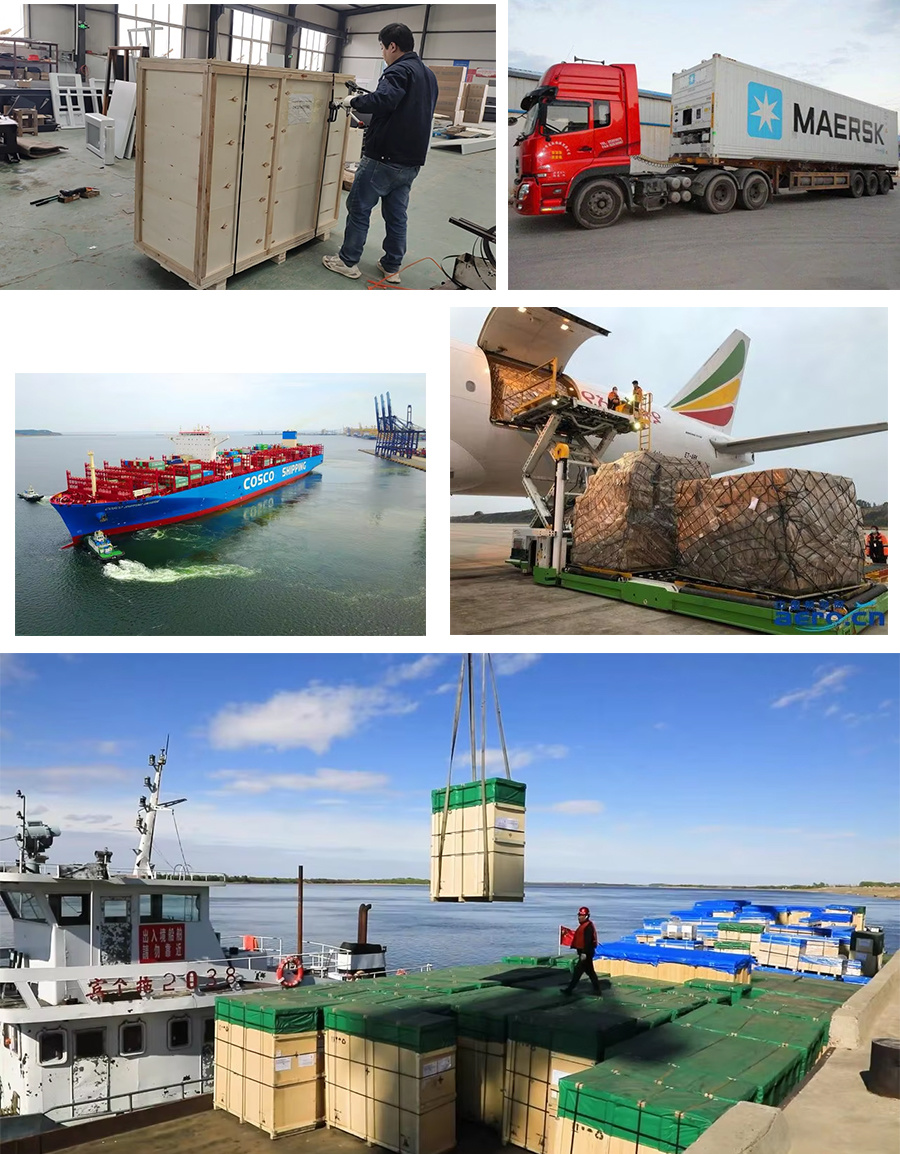

Shipping and Delivery

1. Whole film packaging tube laser cutting machine;

2. Anti-collision package edge;

3. Fumigation-free plywood wooden box and pallets with iron binding belt.

4. 20GP / 40GP full container loading

5. EXW, FOB, CIF, DDP are available.

Application Areas

Company Profile

Jinan Yihai Laser Technology Co..Ltd.is located in the beautiful spring city of Jinan, Focus on Laser equipment research and development,production, sales.after-sales service as one.to provide the world with advanced quality Product range covers laser cutting,laser welding, laser cleaning three categories.Be widely used in Industrial, medical, commercial, scientific research, other fields continue to create value for all walks of life.

The laser steel cutting machine is a revolutionary piece of equipment that has transformed the metalworking industry. It uses a high-powered laser beam to precisely cut through steel with remarkable accuracy and speed.

This advanced machine offers several key features and benefits. Firstly, the laser cutting process is highly precise, allowing for intricate designs and complex shapes to be achieved with ease. It can cut steel with a thickness ranging from thin sheets to thicker plates, providing flexibility in various applications. The laser beam creates clean and smooth cuts, minimizing the need for further finishing.

The laser steel cutting machine also offers exceptional efficiency. It can complete cutting operations in a fraction of the time compared to traditional methods, significantly increasing productivity. The automated nature of the machine reduces the reliance on manual labor, ensuring consistent results and minimizing errors.

Furthermore, this machine is capable of handling a large volume of work. It can continuously operate for extended periods without significant wear and tear, making it suitable for high-demand industrial settings. The durability and reliability of the laser steel cutting machine make it a valuable asset for any manufacturing facility.

In addition to its cutting capabilities, some laser steel cutting machines may also offer additional functions such as engraving and marking. This allows for customization and identification of the steel parts, adding value to the final products.

The laser steel cutting machine is widely used in various industries, including automotive, aerospace, construction, and electronics. It enables the production of high-quality components and parts with tight tolerances, meeting the stringent requirements of these sectors.

With its cutting-edge technology and numerous advantages, the laser steel cutting machine is an essential tool for modern metalworking. It empowers manufacturers to achieve greater precision, efficiency, and productivity, driving innovation and growth in the industry. Whether for small-scale workshops or large industrial operations, the laser steel cutting machine is a game-changer that continues to shape the future of steel cutting.

FAQ

Q: What about the leadtime?

Q: Do you have after sales support?

Q: How about warranty?

Q: Do you have CE document and other documents for customs clearance?

Sheet And Tube Fiber Laser Cutting Machines

GET A FREE QUOTE