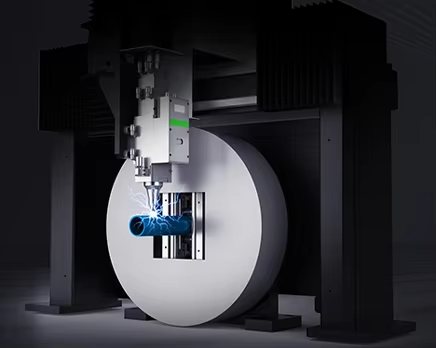

Two-chuck laser tube cutting machine

这里是标题一h1占位文字

Classification :

Product Description

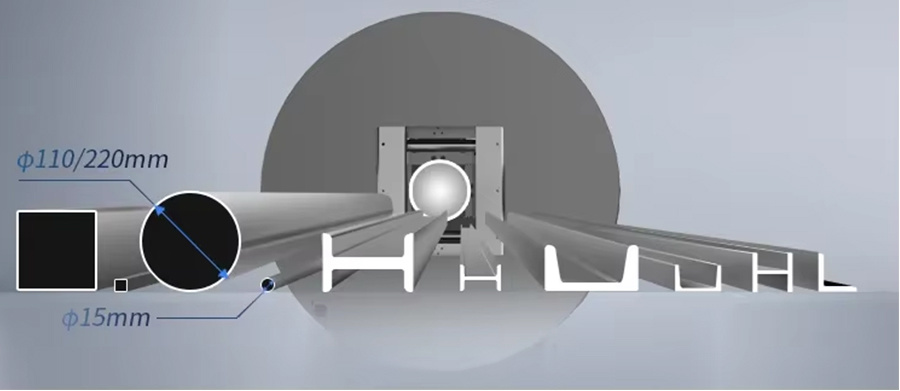

Fiber laser cutting equipment is suitable for stainless steel pipes, low carbon steel pipes, carbon steel pipes, alloy steel pipes, spring steel pipes, iron pipes, galvanized iron pipes, galvanized pipes, aluminum pipes, copper pipes and other pipes and U-shaped, L-shaped, H-shaped and other profile metal cutting. Different cutting thickness depends on the different laser power selection of the metal plate laser cutting machine.

Product Specifications

| No | Item | Data |

|---|---|---|

| 1 | Product Name | Two-chuck Fiber Laser Tube Cutting Machine |

| 2 | Laser Power | 1000W 2000W 3000W 6000W |

| 3 | Laser source | Reci/ MAX/ Raycus |

| 4 | Laser head | Raytools |

| 5 | Control system | WEIHONG |

| 6 | Water chiller | S&A |

| 7 | Driver system | YASKAWA |

| 8 | Guiderail brand | HIWIN |

| 9 | Working voltage | 220V |

| 10 | Certification | CE |

| 11 | Cutting thickness | 0-16mm |

Product Configuration

|

Fully automatic pneumatic double chuck. The professional pneumatic double chuck can automatically center and clamp the workpiece during work. The air pressure can be adjusted simultaneously to keep the clamping force stable and reliable. |

|

Raytools Laser Head. Raytools fiber laser cutting head with Anti-crash function, good sealed,high Pressure resistant, auto- tracking system and anti-crash and stop system can protect good cutting quality and longer the life of lens. |

|

High precision Bed. High quality square tube welding and three pass welding process are adopted, which are sturdy and durable. Machine bed can maintain good mechanical properties such as tensile strength, toughness, hardness and deformation resistance. |

|

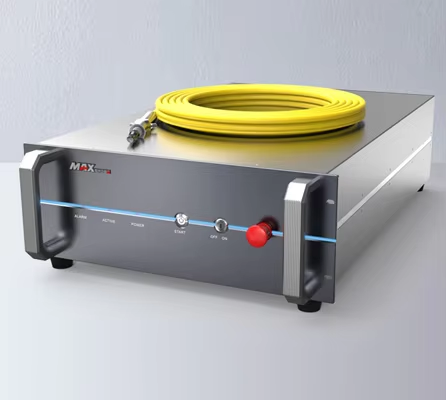

MAX Laser Source . Famous laser brand all over the world ,High electronic-optical conversion.The center wavelength is 1080nm+-5. efficiency, good beam quality, wide modulation frequency, high reliability, long life and maintenance-free. |

|

S&A/Hanli water chiller . 1. With environmental refrigerant; 2. ±1℃ precise temperature control; 3. The intelligent temperature controller has 2 control modes, applicable to different applied occasions; with various setting and display functions; |

Application Areas

Company Profile

Jinan Yihai Laser technology CO.,LTD is established in 2009, Yihai Laser is a professional manufacturer and exporter that is concerned with the design, development and production of laser machines, located in Jinan City,Shandong Province.

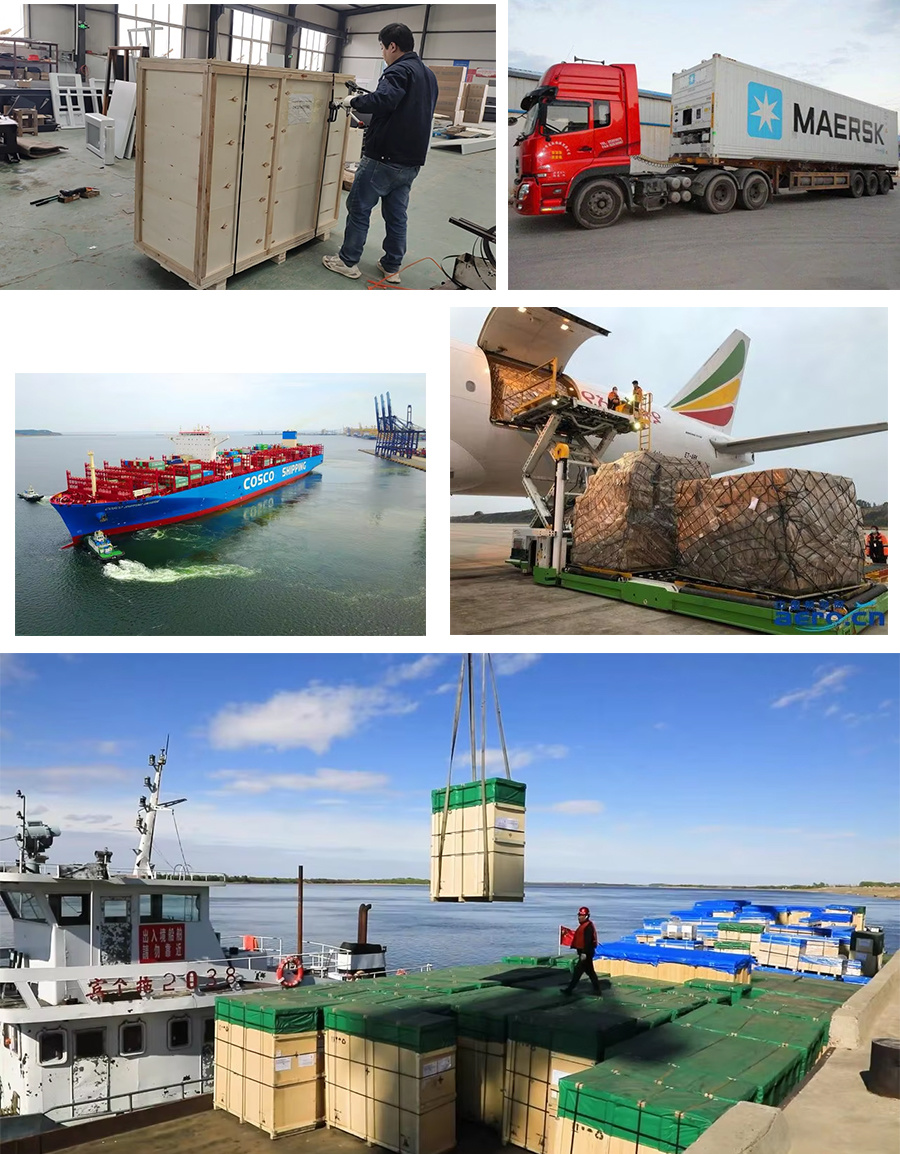

Shipping and Delivery

Package

1) Whole film packaging machine.

2) Anti-collision package edge.

3) Fumigation-free plywood wooden box with an iron-binding belt.

4) According to the customer's requirements for loading the whole container or LCL at Qingdao Port.

Delivery Terms

1) The machine will be produced after received your deposit, its need about 15-20 working days to produce the machine after get your deposit.

2) After the machine is ready, we will test it very carefully, and ensure everything is OK.

3) Then we will show you the machine photos and the testing video.

4) After you agree, please finish the balance payment.

5) Finally, all things are tested well, then we arrange the delivery.

The laser steel cutting machine is a remarkable technological marvel that has revolutionized the field of metal fabrication. It combines precision, speed, and efficiency to deliver outstanding results.

This advanced machine utilizes a high-intensity laser beam to slice through steel with extraordinary accuracy. The laser's focused energy allows for extremely fine cuts, enabling the creation of complex geometries and intricate designs that were once difficult to achieve.

One of the key features of the laser steel cutting machine is its ability to handle a wide range of steel thicknesses. Whether it's thin sheets or thick plates, the machine can effortlessly make clean and precise cuts, ensuring high-quality end products.

The cutting process is highly automated, minimizing the need for human intervention and reducing the chances of errors. Operators can simply program the desired cutting patterns and parameters, and the machine will execute the task with precision and reliability.

The laser steel cutting machine also offers exceptional speed. It can complete cutting operations in a matter of seconds, significantly enhancing productivity and allowing for shorter production cycles. This is especially beneficial in industries where time is of the essence.

In addition to its cutting capabilities, some models may come with additional features such as bevel cutting or the ability to cut different types of metals. This added flexibility makes the machine even more versatile and suitable for a wide range of applications.

Moreover, the laser beam produces minimal heat-affected zones, ensuring that the integrity and properties of the steel are maintained. This is crucial for applications where the quality and performance of the cut parts are of utmost importance.

The laser steel cutting machine is widely used in various industries, including automotive, aerospace, manufacturing, and construction. It allows for the production of precision components, structural elements, and decorative pieces with ease.

With its advanced technology, high performance, and user-friendly interface, the laser steel cutting machine is a game-changer in the world of metalworking. It empowers businesses to meet the increasing demands for high-quality, custom-made steel products in a timely and efficient manner. Whether for large-scale industrial operations or smaller workshops, this machine is an essential tool that continues to drive innovation and growth in the metal fabrication industry.

FAQ

Q: What about the leadtime?

Q: Do you have after sales support?

Q: How about warranty?

Q: Do you have CE document and other documents for customs clearance?

Two-chuck laser tube cutting machine

GET A FREE QUOTE