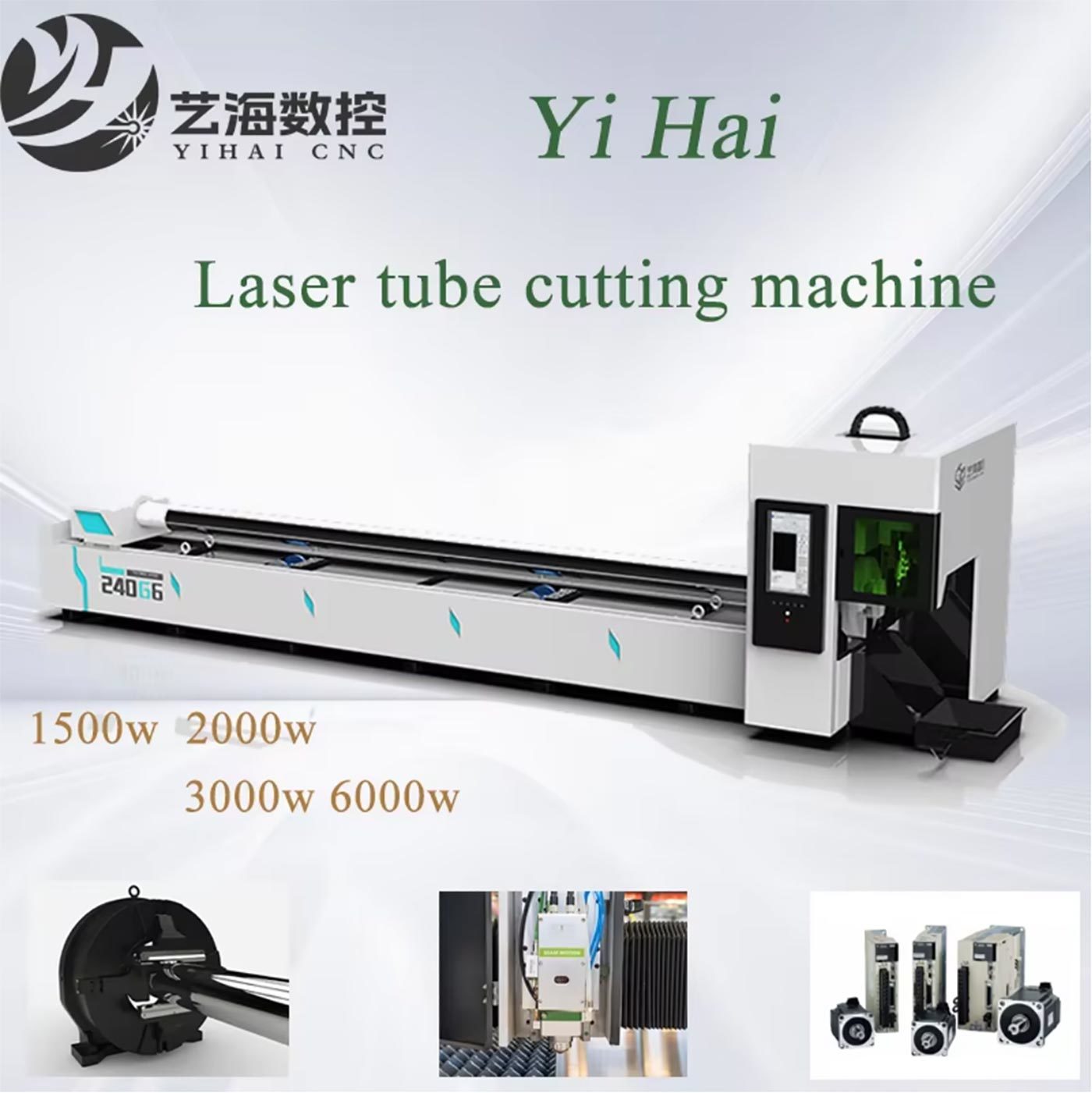

china Tube laser cutting machine

Release time:

2025-04-16

A tube laser cutting machine is a highly precise tool. It uses a laser beam to cut tubes of various materials such as metal. It offers high - speed cutting, accurate shaping, and can handle complex geometries. This machine is favored in industries like automotive, aerospace, and construction for its efficiency and quality output.

Product Description

Surprise Price 1500w/3000w/4000w/6000w Raycus Cnc Laser Tube/pipe Cutting Machine For Metal Tubes/Pipes With Factory Price

No | Item | Data |

1 | Product Name | Tube Laser Cutting Machine |

2 | Laser Power | 1500W 2000W 3000W 4000W 6000W |

3 | Max Moving Speed | 160m/min |

4 | Fiber Laser Source | Raycyus /Max/ IPG |

5 | Cutting Head | Raytools / Precitec/Au3tech |

6 | Control System | CpyCut |

7 | Ruducer | Japanese Shimpo/ French Motovario/ Germany Neugart |

8 | Guide | Taiwan Hiwin/Italy PEK |

9 | Water chiller | Hanli/Tongfei/S&A,etc. |

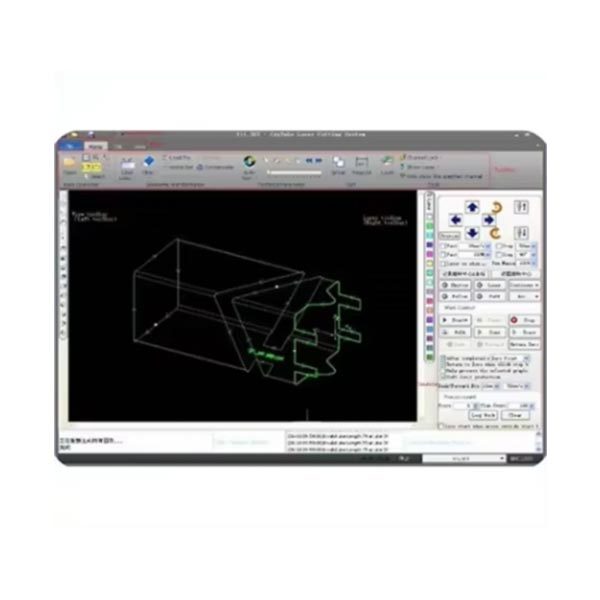

10 | Compatible Software | CorelDraw/AutoCAD/Photoshop/AI |

11 | Clamping Diameter | 20-160mm/ 20-220mm/ 20-350mm |

12 | Cutting Size | 6000mm / 9000mm length |

Product configuration

| Laser cutting head 1.We choose Raytools laser cutting head. The focal length adjustment range is large from 1mm to 20mm. 2.Accuracy is high, deviation is within 0.02mm.Auto focus, always keep a distance of 0.02mm from the cutting surface. Service life is about 4000 hours. 3.High stability and good cutting quality,fast piercing and cutting. |

| Title goes here. 1.A fiber laser , globally influential, production and service provider with the ability to integrate from materials, devices to complete machines. 2.Raycus / MAX / BWT /IPG (optional), with higher photo electric conversion efficiency, lower power consumption and higher beam quality 3.Fiber lasers have the advantages of small size, low energy consumption, long life, high stability, |

| Control system Cypcut control system: the leader in laser cutting systems。Laser cutting control system: It is the brain of the laser cutting machine. It plans a reasonable cutting path that maximizes the use of materials through a certain algorithm, controls the cutting equipment to follow the path, and completes the cutting work accurately and efficiently according to the processing technology. |

| Servo Motor Imported from japan, use top brand Yaskawa, Fuji, etc. High power motor system on X,Y,Z axis. High precision give better cutting effect, high speed give faster cutting speed. |

| Auto Chunk Chunk is for dual use plate&pipe cutting machine. It adopts the pneumatic chunk clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-240 mm. |

| Working table-guide rail, rack HIWIN linear guides and APEX helical racksare used in conjunction with each other,with high guiding accuracy and smooth movement, which can improve the accuracy and stability of the equipment greatly. |

| Industrial Machine bed A solid bed has high stability .It is unmatched by other materials and structures. The use of graphite cast iron as a raw material keeps the precision of the machine tool for a long time and remains unchanged for 50 years. |

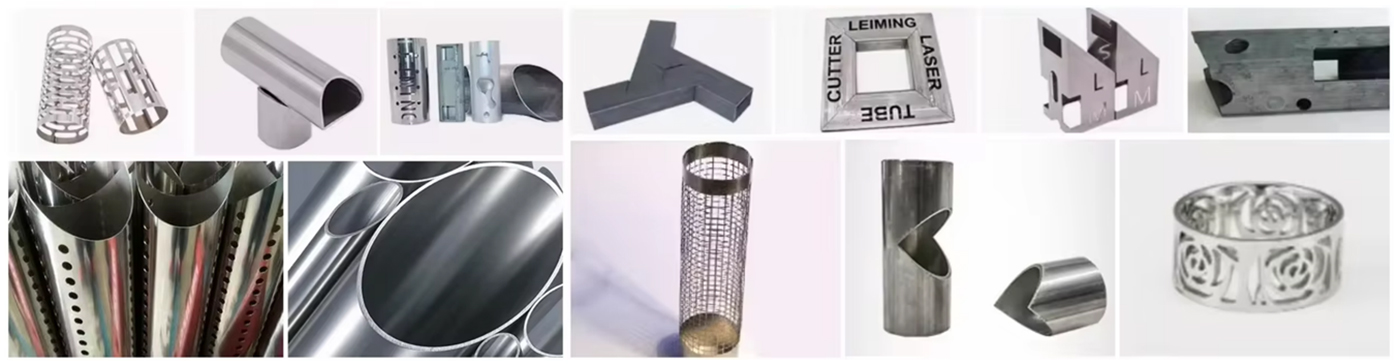

Application description

This machine can be used in carbon steel, stainless steel pipe, galvanized pipe, electrolytic pipe, aluminum alloy pipe, brass and copper and other metal materials. Pipe laser cutting machine can be widely used in Industrial, medical, scientific research, military and other fields continue to create value for all walks of life.

Factory description

Jinan Yihai Laser Technology Co. Ltd. Is located in the beautiful spring city of Jinan Focus on Laser equipment research and development, production, sales, after-sales service as one, to provide the world with advanced quality, Product range covers laser cutting, laser welding, laser cleaning three categories. Be widely used in industrial, medical,commercial, scientific research, military and other fields continue to create value for all walks of life.

YH laser trustworthy to win the market with quality, higher than the international and industry standards Establish quality assurance system, implement comprehensive quality management,and carry out all aspects of production Strict quality control,excellence.

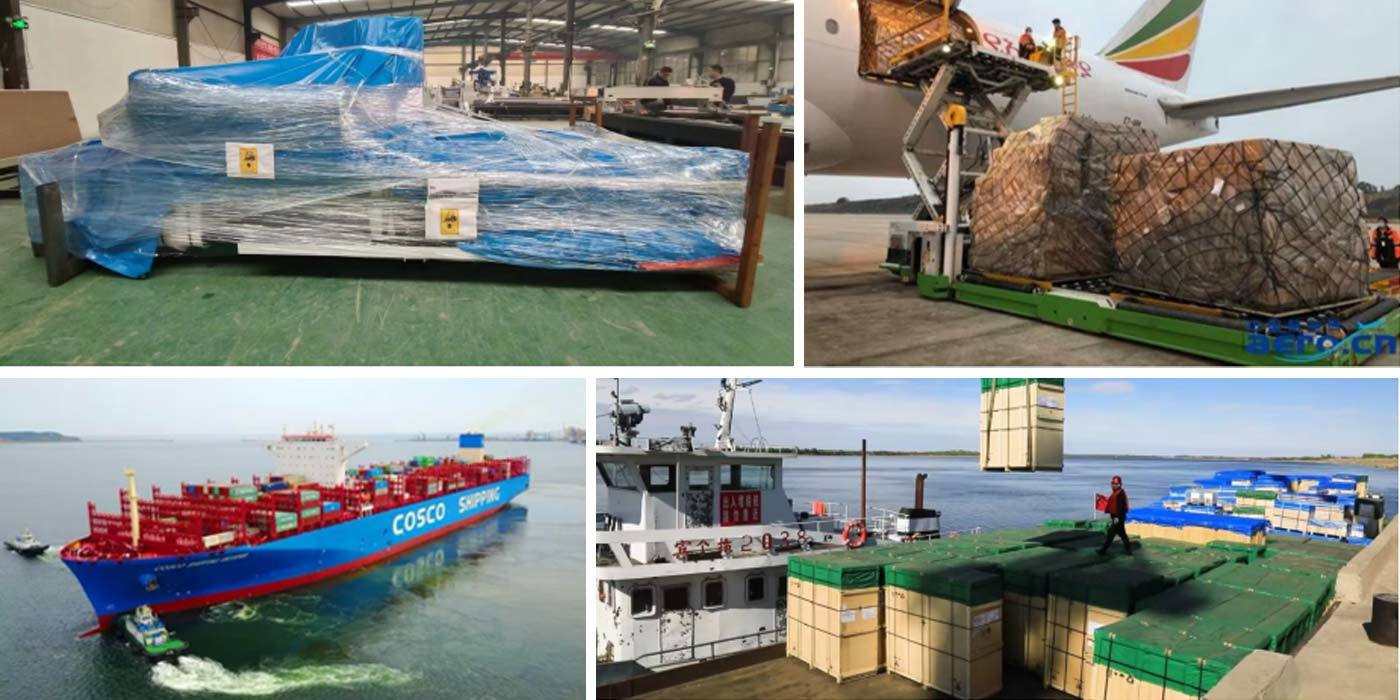

Shipping Packaging

Our company cooperates with more than 10 logistics companies, with transportation routes covering more than 150 countries and regions around the world. Provide strong guarantee for product transportation. Under normal circumstances, product delivery can be completed within 30-45 working days.

(1)Two year quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge when if any problem during the warranty period.

(2) Lifetime maintenance free of charge.

(3) Free training course at our plant.

(4) 18 hours on line service each day, free technical support.

(5) Machine has been adjusted before delivery. We will take machine photos and make machine working image for you ,after getting your agreement ,then we will book a ship.

(6) Providing technical services to the door(We have professional engineers to offer machine installation commissioning and maintenance).

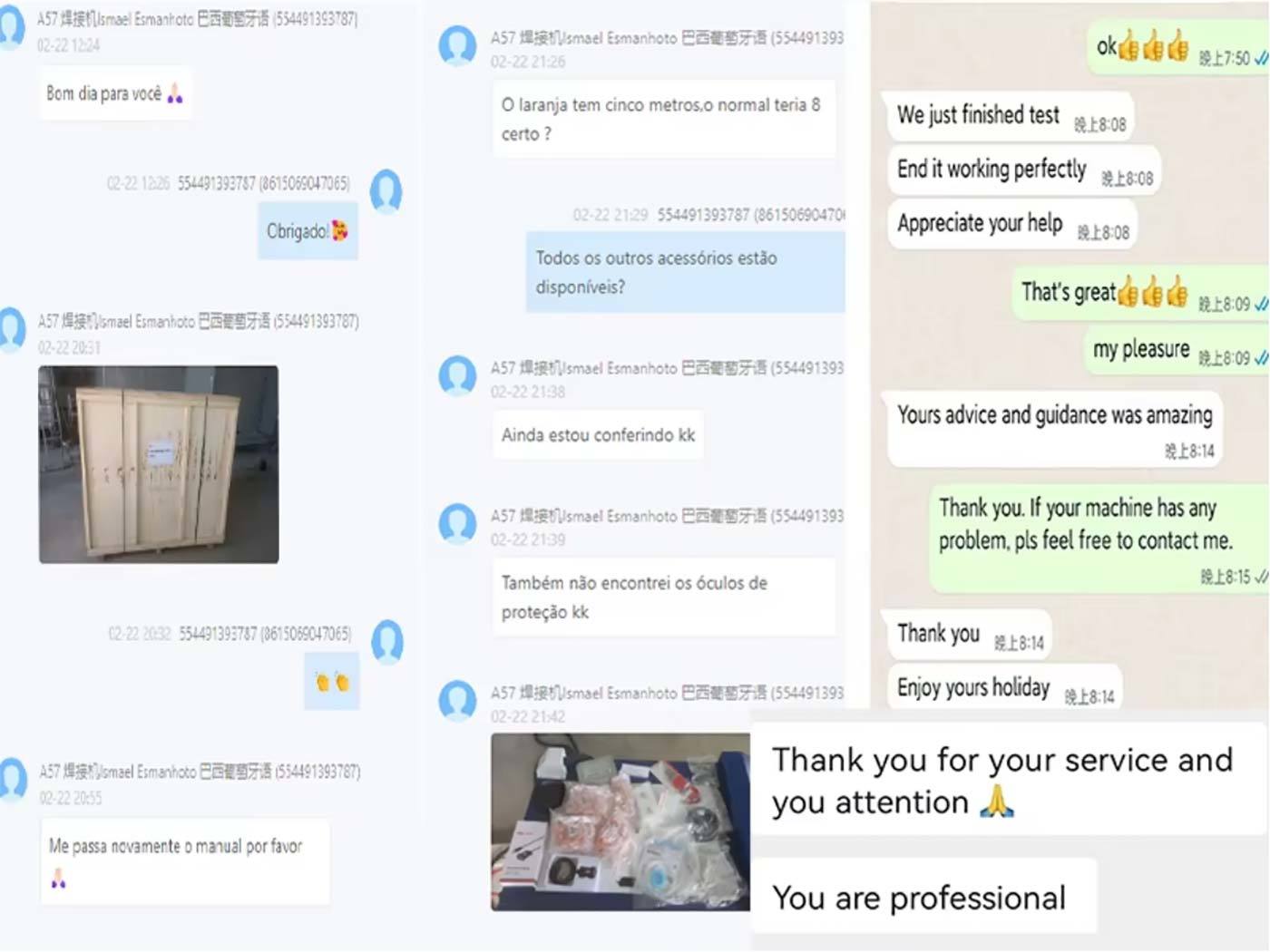

(7) If you have any problem during your use. you need our technician to judge where the problem is and help you to solve it. We can provide team viewer and skype with cam till all of your problems solved.

Why Choose Us?

FAQ

Q1: Our workers can't operate the machine, how to train the staff?

A:We will send you the teaching video of the machine and 24-hour online service,we also support free training service engineers can train your workers for free in our factory for 1-3 days,if you want door-to-door service,We can arrange local service in 48 hours.

Q2: I don’t know which one is suitable for me?

A:Please tell me your 1) Your materials 2) Max size of your material 3) Max cut thickness 4) Popular cut thickness.

Q3: It's not convenient for me to go to China, but I want to see the condition of the machine in the factory. What should I do?

A:We support the production visualization service. The sales department who responds to your inquiry for the first time will be responsible for your follow-up work.

Q4: Do you have CE document and other documents for customs clearance?

A:Yes,we have Original. At first we will show you and And after shipment we will give you CE/Packing list/Commercial Invoice/Sales contract for customs clearance.

Q5: I don’t know how to use after I receive Or I have problem during use,how to do?

A:1) We have detailed user manual with pictures and CD,you can learn step by step.And our user manual update every month for your easy learning if there is any update on machine. 2) If have any problem during use,you need our technician to judge the problem elsewhere will be solved by us. Our sales sunny and after-sales technician can provide team viewer/Whatsapp/Email/Phone/Skype with camera till all of your problems finished.We can also provide Door service if you need.

Q6: Why does the machine price not include fiber sources and tube components?

A:Because you can customize the generator, rotary and other configurations, the price is the base bed price.

The Tube Laser Cutting Machine is a state-of-the-art solution designed for high-precision cutting of tubular and profile materials. Ideal for industries such as automotive, aerospace, construction, and furniture, this machine delivers unmatched accuracy, speed, and flexibility. Whether you're working with round, square, rectangular, or oval tubes, this machine ensures clean, burr-free cuts with minimal material waste.

Equipped with advanced fiber laser technology, the tube laser cutter offers superior cutting performance on a wide range of materials, including stainless steel, carbon steel, aluminum, and copper. Its CNC-controlled system allows for seamless integration with CAD/CAM software, enabling complex designs and intricate patterns to be executed with ease. The machine's automatic loading and unloading system further enhances productivity, reducing downtime and labor costs.

Key features include a rotary chuck system for 360-degree cutting, ensuring consistent precision across all angles, and a laser cutting head with automatic focus adjustment for optimal beam quality. The high-speed cutting capability ensures faster production cycles, while the dust extraction system maintains a clean working environment.

Compact yet powerful, the tube laser cutting machine is designed for both small workshops and large-scale manufacturing facilities. Its user-friendly interface and low maintenance requirements make it a cost-effective investment for businesses aiming to boost efficiency and stay competitive.

Upgrade your production capabilities with the Tube Laser Cutting Machine – where innovation meets precision, and versatility meets performance. Experience the future of tube cutting technology today!

Latest News

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison Table of Contents 1. Introduction to Cutting Technologies 2. Understanding Laser Plate Cutting Machines 3. Overview of Traditional Cutting Methods 4. Efficiency Comparison of Laser vs. Traditional Cutting 5. Precision and Quality of Cuts 6. Cost Analysis: Laser Cutting vs. Traditional

2025-06-25

Revolutionizing Surface Cleaning: The Advantages of Backpack Laser Cleaning Machines

--- In recent years, the manufacturing and packaging sectors have witnessed a groundbreaking advancement in cleaning technology—the backpack laser cleaning machine. This innovative device is designed to provide an effective solution for removing contaminants, rust, and old coatings from various surfaces. It employs the power of laser technology, which is not only efficient but also environmentally

2025-06-20

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained Table of Contents 1. Introduction to Luggage Box Laser Cleaning Machines 2. Understanding Laser Cleaning Technology 3. Applications of Luggage Box Laser Cleaning Machines 4. Advantages of Using Laser Cleaning Machines in Packaging 5. The Role of Laser Cleaning Machines in Sustainable Packaging 6. Future

2025-06-15

The laser marking machine is a remarkable device. It precisely etches or marks various materials with laser beams. It offers high accuracy, permanence, and flexibility.

2025-06-11

Revolutionize Your Cleaning Process with Laser Cleaning Machines

In the realm of manufacturing and packaging machinery, maintaining cleanliness is crucial for optimal performance and longevity. One of the most innovative solutions available today is the laser cleaning machine. This technology utilizes high-powered laser beams to effectively remove contaminants, rust, and other unwanted materials from various surfaces, making it a game-changer in industrial clea

2025-06-10

Top Features to Look for in an All-in-One Laser Marking Machine

Top Features to Look for in an All-in-One Laser Marking Machine In today's fast-paced manufacturing environment, **laser marking machines** have emerged as pivotal tools for a wide range of industries. Whether you are engraving identifiers on products or marking barcodes for inventory management, the efficiency and precision of a laser marking machine can significantly impact your operations. Howe

2025-06-05