How to Clean the Lens of Laser Cutting Machine Correctly?

Release time:

2024-07-11

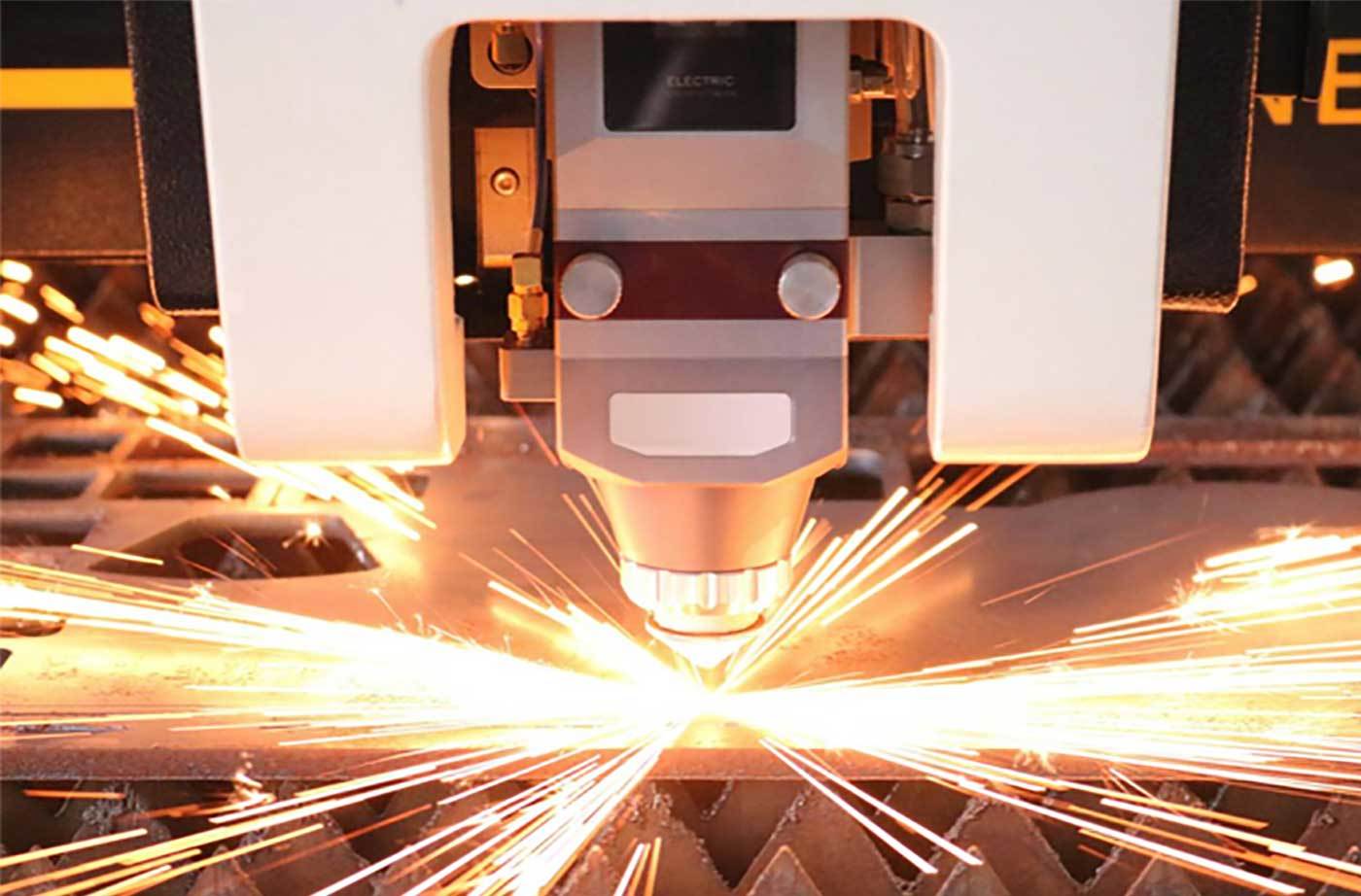

There are various types of lenses for laser cutting machines, such as focusing lenses, protective lenses, etc. But the optical lens in the laser system is consumable. In order to extend the service life of the laser cutting machine as much as possible and reduce usage costs, it is necessary to strictly clean the lenses in accordance with this specification. During the replacement process, attention should be paid to the placement, testing, and installation of optical lenses to prevent damage and contamination.

There are various types of lenses for laser cutting machines, such as focusing lenses, protective lenses, etc. But the optical lens in the laser system is consumable. In order to extend the service life of the laser cutting machine as much as possible and reduce usage costs, it is necessary to strictly clean the lenses in accordance with this specification. During the replacement process, attention should be paid to the placement, testing, and installation of optical lenses to prevent damage and contamination.

Precautions before cleaning lenses:

1. Please be sure to wear finger covers or rubber gloves to install the lenses.

2. Prohibit sharp instruments to avoid scratching the surface of the lens.

3. When removing lenses, hold the edges of the lenses to avoid contact with the film layer. The environment for testing and cleaning the lenses must be dry and clean.

4. The workbench must maintain several layers of clean tissue and several cleaning lenses.

5. Do not speak above the camera and keep potential pollutants (such as food, beverages, etc.) away from the working environment.

Operating steps for correctly cleaning lenses:

1 Blow out floating objects on the surface of the original parts by blowing a balloon.

2 Use analytical pure acetone to gently clean the lens. Cleaning should be completed in one go to avoid the generation of wavy ribs.

3 If acetone cannot remove all dirt, clean with acid vinegar.

4 When pollutants and lens damage cannot be removed and removed, the only way to restore good performance is to replace the lens.

When we using the machine, the lenses should be properly cleaned and operated, so that their lifespan and performance will undoubtedly be significantly improved. This is also one of the ways we ensure the lifespan and stability of the laser cutting machine. More prevention and maintenance can make the laser cutting machine work longer and have higher stability.

Latest News

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison Table of Contents 1. Introduction to Cutting Technologies 2. Understanding Laser Plate Cutting Machines 3. Overview of Traditional Cutting Methods 4. Efficiency Comparison of Laser vs. Traditional Cutting 5. Precision and Quality of Cuts 6. Cost Analysis: Laser Cutting vs. Traditional

2025-06-25

Revolutionizing Surface Cleaning: The Advantages of Backpack Laser Cleaning Machines

--- In recent years, the manufacturing and packaging sectors have witnessed a groundbreaking advancement in cleaning technology—the backpack laser cleaning machine. This innovative device is designed to provide an effective solution for removing contaminants, rust, and old coatings from various surfaces. It employs the power of laser technology, which is not only efficient but also environmentally

2025-06-20

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained Table of Contents 1. Introduction to Luggage Box Laser Cleaning Machines 2. Understanding Laser Cleaning Technology 3. Applications of Luggage Box Laser Cleaning Machines 4. Advantages of Using Laser Cleaning Machines in Packaging 5. The Role of Laser Cleaning Machines in Sustainable Packaging 6. Future

2025-06-15

The laser marking machine is a remarkable device. It precisely etches or marks various materials with laser beams. It offers high accuracy, permanence, and flexibility.

2025-06-11

Revolutionize Your Cleaning Process with Laser Cleaning Machines

In the realm of manufacturing and packaging machinery, maintaining cleanliness is crucial for optimal performance and longevity. One of the most innovative solutions available today is the laser cleaning machine. This technology utilizes high-powered laser beams to effectively remove contaminants, rust, and other unwanted materials from various surfaces, making it a game-changer in industrial clea

2025-06-10

Top Features to Look for in an All-in-One Laser Marking Machine

Top Features to Look for in an All-in-One Laser Marking Machine In today's fast-paced manufacturing environment, **laser marking machines** have emerged as pivotal tools for a wide range of industries. Whether you are engraving identifiers on products or marking barcodes for inventory management, the efficiency and precision of a laser marking machine can significantly impact your operations. Howe

2025-06-05