How to solve the problem of high temperature of the protective mirror under the laser head?

Release time:

2024-12-12

The high temperature issue of the protective mirror under the laser head in fiber laser cutting machines has been a cause of concern for many operators. The heat generated during the cutting process can lead to damage and reduced efficiency of the mirror, affecting the overall performance of the machine.

The high temperature issue of the protective mirror under the laser head in fiber laser cutting machines has been a cause of concern for many operators. The heat generated during the cutting process can lead to damage and reduced efficiency of the mirror, affecting the overall performance of the machine.

To address this problem, experts recommend several solutions. One approach is to improve the cooling system of the machine, ensuring that the mirror is kept at a lower temperature during operation. This can be achieved by increasing the flow rate of coolant or using a more efficient cooling method, such as liquid cooling.

Another solution is to optimize the cutting parameters to reduce the amount of heat generated during the process. By adjusting the power, speed, and focus of the laser beam, operators can minimize the heat transferred to the mirror and prevent overheating.

Regular maintenance and cleaning of the protective mirror are also crucial in preventing temperature-related issues. Dust and debris can accumulate on the surface of the mirror, insulating it and causing it to heat up quickly. By keeping the mirror clean and free of obstructions, operators can ensure that it operates at a safe temperature.

Furthermore, using high-quality protective mirrors with better heat resistance can help mitigate the problem. Investing in mirrors made of durable materials that can withstand high temperatures will prolong their lifespan and improve the overall performance of the laser cutting machine.

Of course, specifically:

The high temperature of the protective mirror under the laser head is most likely caused by the following reasons:

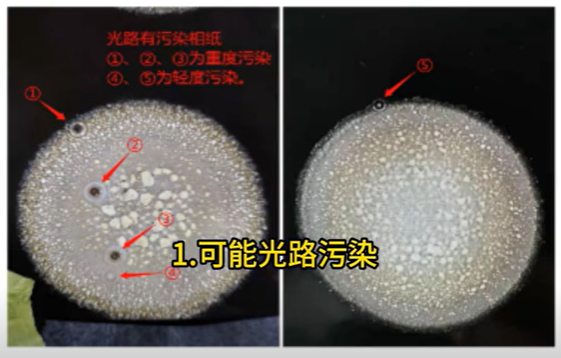

1. Possible light path pollution

The energy distribution of uncontaminated photo paper is uniform, with no dark spots or black dots.

Contaminated photo paper will show regular circular dark spots or obvious black dots.

Use photo paper and white light to detect the light path

2. Blow with air or the gas that triggers the alarm

Blow with air for 3-5 minutes and then do a spot shot. If the temperature of the protective lens becomes high, it proves that the pipeline is contaminated and the air pipeline needs to be cleaned or the air compressor filter element needs to be replaced.

3. Caused by the perforation process

Adjustment method:

(1). Reduce the frequency by 10% in sequence

(2). Reduce the spot-to-air ratio by 5%

(3). Reduce the air pressure by 0.05ba

(4). It may also be that the quality of the protective lens is not good

Try to replace another lens

Latest News

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison

Laser Plate Cutting Machines vs. Traditional Cutting Methods: A Comprehensive Comparison Table of Contents 1. Introduction to Cutting Technologies 2. Understanding Laser Plate Cutting Machines 3. Overview of Traditional Cutting Methods 4. Efficiency Comparison of Laser vs. Traditional Cutting 5. Precision and Quality of Cuts 6. Cost Analysis: Laser Cutting vs. Traditional

2025-06-25

Revolutionizing Surface Cleaning: The Advantages of Backpack Laser Cleaning Machines

--- In recent years, the manufacturing and packaging sectors have witnessed a groundbreaking advancement in cleaning technology—the backpack laser cleaning machine. This innovative device is designed to provide an effective solution for removing contaminants, rust, and old coatings from various surfaces. It employs the power of laser technology, which is not only efficient but also environmentally

2025-06-20

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained

The Future of Packaging: Luggage Box Laser Cleaning Machines Explained Table of Contents 1. Introduction to Luggage Box Laser Cleaning Machines 2. Understanding Laser Cleaning Technology 3. Applications of Luggage Box Laser Cleaning Machines 4. Advantages of Using Laser Cleaning Machines in Packaging 5. The Role of Laser Cleaning Machines in Sustainable Packaging 6. Future

2025-06-15

The laser marking machine is a remarkable device. It precisely etches or marks various materials with laser beams. It offers high accuracy, permanence, and flexibility.

2025-06-11

Revolutionize Your Cleaning Process with Laser Cleaning Machines

In the realm of manufacturing and packaging machinery, maintaining cleanliness is crucial for optimal performance and longevity. One of the most innovative solutions available today is the laser cleaning machine. This technology utilizes high-powered laser beams to effectively remove contaminants, rust, and other unwanted materials from various surfaces, making it a game-changer in industrial clea

2025-06-10

Top Features to Look for in an All-in-One Laser Marking Machine

Top Features to Look for in an All-in-One Laser Marking Machine In today's fast-paced manufacturing environment, **laser marking machines** have emerged as pivotal tools for a wide range of industries. Whether you are engraving identifiers on products or marking barcodes for inventory management, the efficiency and precision of a laser marking machine can significantly impact your operations. Howe

2025-06-05