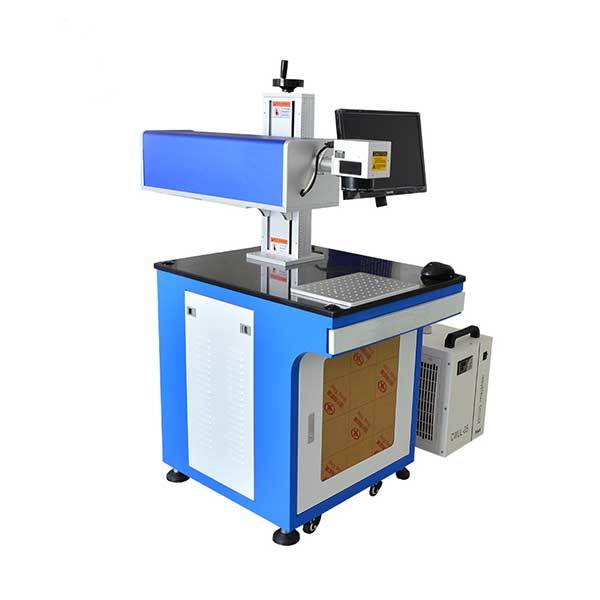

UV laser marking machine

Release time:

2025-02-19

A UV laser marking machine is a high - precision device. It uses ultraviolet laser beams for marking. With a short wavelength, it can create fine, high - contrast marks on various materials like plastics, metals, and glass.

A UV laser marking machine is a high - precision device. It uses ultraviolet laser beams for marking. With a short wavelength, it can create fine, high - contrast marks on various materials like plastics, metals, and glass. It offers non - contact marking, high - speed operation, and is widely used in industries for product identification.

The laser marking machine is a revolutionary device that offers precise and permanent marking on a wide range of materials.

This advanced technology uses a focused laser beam to create marks that are highly detailed and accurate. It can mark various substances such as metals, plastics, glass, ceramics, and more. The laser marking process is non-contact, ensuring that the material remains undamaged during marking.

One of the outstanding features of the laser marking machine is its high precision. It can create extremely fine marks, even on small or complex objects. This allows for detailed logos, serial numbers, barcodes, and other important information to be accurately engraved or marked. The marking is also highly consistent, ensuring uniformity across multiple pieces.

The speed of the laser marking machine is another significant advantage. It can mark large quantities of items in a short period, increasing productivity and efficiency in industrial settings. The machine can be programmed to perform automated marking, reducing the need for manual labor and minimizing errors.

The laser marking machine also offers great flexibility. It can be adjusted to create different mark depths, intensities, and styles, depending on the specific requirements. This enables it to handle a diverse range of marking tasks, from simple identification marks to elaborate designs.

In addition to its marking capabilities, some laser marking machines may have additional features. For example, they might be capable of marking in different colors by using special coatings or materials. Some models may also have the ability to mark on curved or irregular surfaces, expanding their application range.

The durability of laser marks is another important aspect. The marks are resistant to fading, scratching, and other forms of wear, ensuring that the marked information remains legible for a long time. This is crucial in applications where traceability and permanence are essential.

The laser marking machine finds extensive use in various industries. In the manufacturing sector, it is used for marking parts, components, and products for identification and traceability. It is also widely employed in the electronics industry for marking circuit boards and devices. The jewelry and watchmaking industries utilize it for adding intricate designs and branding. Additionally, it is used in the medical and aerospace fields for marking instruments and components.

Furthermore, the laser marking machine offers a clean and environmentally friendly marking solution. There are no chemicals or inks involved, reducing waste and potential pollution. It also operates quietly, creating a more pleasant working environment.

Overall, the laser marking machine is a cutting-edge technology that provides accurate, efficient, and durable marking. With its diverse features and applications, it has become an essential tool in many industries, enabling manufacturers and businesses to add value and ensure the quality and traceability of their products.

Latest News

Revolutionizing Metal Fabrication: The Benefits of Laser Steel Cutting Machines

Laser steel cutting machines represent a significant advancement in the field of industrial fabrication, fundamentally changing the way metal components are produced. These machines utilize highly focused laser beams to cut through steel and other metals with remarkable precision. This technology is not only efficient but also offers a level of accuracy that is difficult to achieve with traditiona

2025-05-01

Exploring the Future of Manufacturing: The Advancements in Laser Cutting Technology

Exploring the Future of Manufacturing: The Advancements in Laser Cutting Technology Table of Contents 1. Introduction to Laser Cutting Technology 2. The Evolution of Laser Cutting in Manufacturing 3. Advantages of Laser Cutting over Traditional Methods 3.1 Precision and Accuracy 3.2 Versatility of Materials 3.3 Reduced Waste and Cost-Effectiveness 4. Innovations in Laser Cutting Tech

2025-04-26

Maximizing Efficiency in Manufacturing with Plate Cutting Machines

In the manufacturing sector, efficiency and precision are paramount. One of the essential tools that can significantly enhance these aspects is the plate cutting machine. These machines are designed to cut various types of plates, including metal, plastic, and composite materials, making them versatile for a range of applications in manufacturing and fabrication. Plate cutting machines employ diff

2025-04-21

Achieving Precision: Techniques for Accurate Cuts with Sheet Cutting Machines

Achieving Precision: Techniques for Accurate Cuts with Sheet Cutting Machines Table of Contents Introduction to Sheet Cutting Machines Understanding Precision in Sheet Cutting Types of Sheet Cutting Machines Key Techniques for Accurate Cuts Importance of Material Selection Setting Up Your Sheet Cutting Machine for Success Maintenance and Calibration Tips for Optimal Pe

2025-04-16

Unlocking Precision: The Advantages of Laser Plate Cutting Machines

Laser plate cutting machines represent a groundbreaking advancement in the field of manufacturing and metal processing. These machines utilize high-powered lasers to cut through various types of materials, providing manufacturers with unparalleled precision and efficiency. Whether you're working with steel, aluminum, or other metals, laser cutting technology offers distinct advantages over traditi

2025-04-11